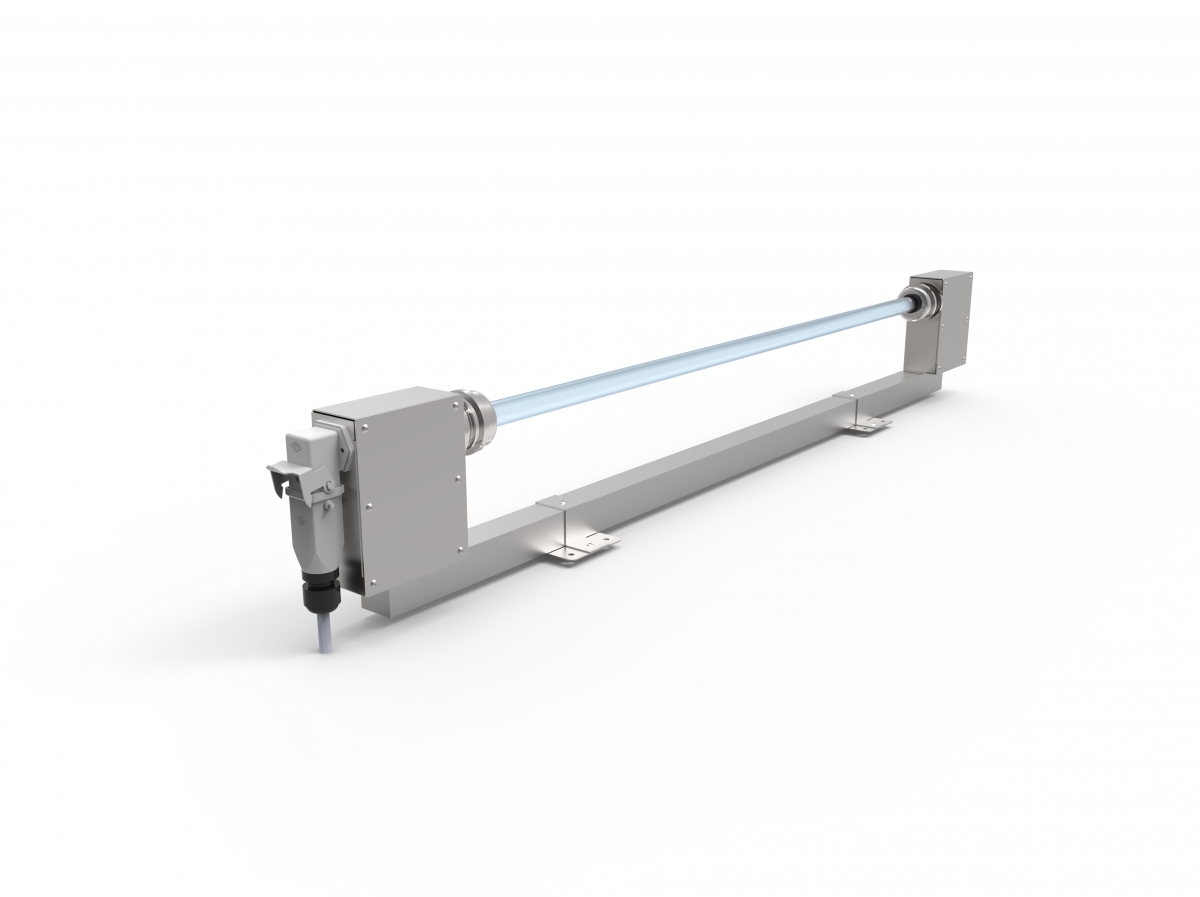

UV-SMELL-A is composed of:

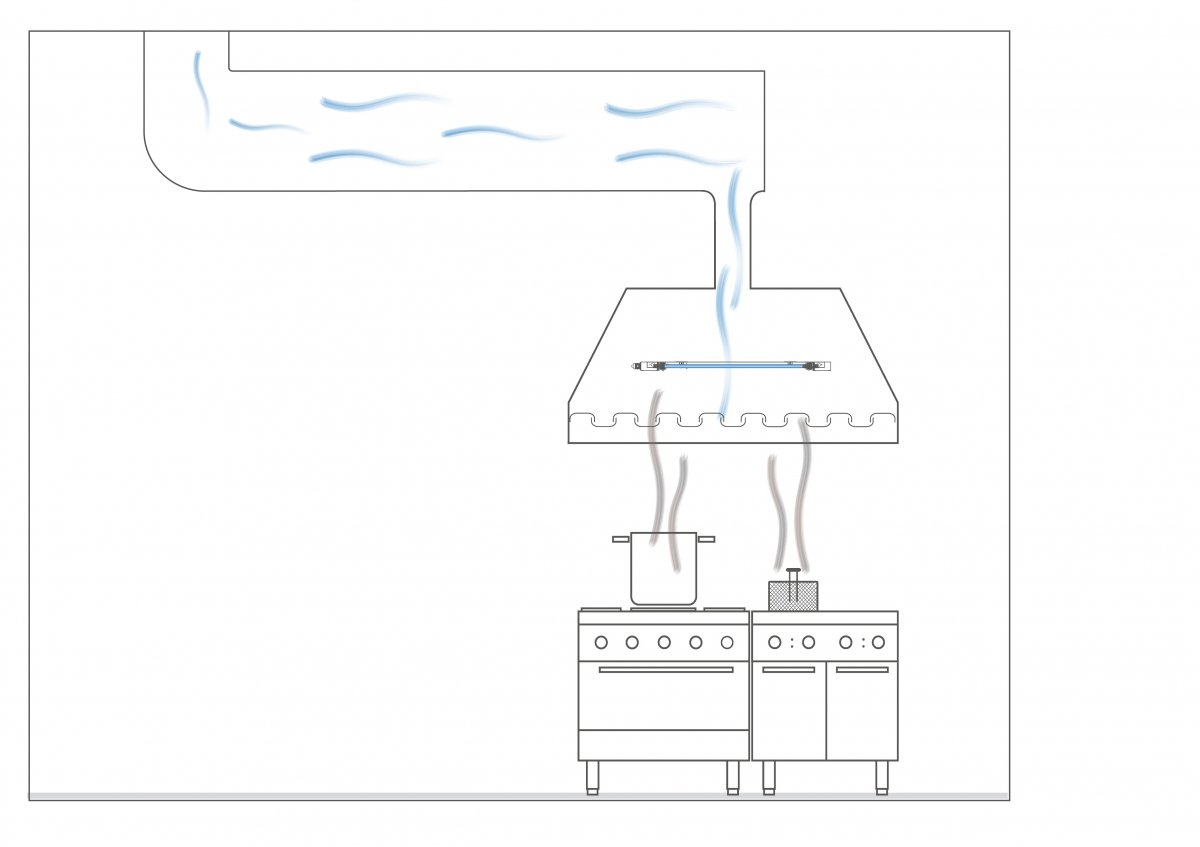

UV-SMELL-A can be installed directly inside the hood, directly inside the centralized apiration and filtration system. The air flow must pass entirely through th section with UV-C amalgam lamp placed on its Stainless Steel AISI 304 body.

The module is designed to be mounted alternatively or together with Light Progress special TiOx® filter, coated with nano-structured titanium dioxide and silver salts (optional) that, in combination with the very high UVC power emitted by lamps, is an excellent photo-catalyst that degrades pollutants and organic and inorganic compounds (SOV, NOx and VOC volatile organic compounds, nitrogen oxides). TiOx® filter performs further oxidation of polluting particles, and contributes significantly to the deodorizing action of UV-C.

The special materials used for UVSMELL-SQ ensures watertight (IP 55) protection, high temperatures (45/50 °C) resistance, as well as endurance to fats and oils.

UV-SMELL-A

In restaurants or industrial/ community kitchens, during food cooking phases, fats, pollutants and unpleasant smells are generated; this may be disputed by authorities and give often rise of legal issues with the neighborhood.Applied inside kitchen hoods and aspiration systems, UV-SMELL-A contributes significantly to minimize these problems; fats are carbon and hydrogen compounds, with a structure made of complex chains. If fats are exposed to an intense UV-C irradiation, they absorb part of this powerful energy, and molecules, placed in a higher energy state, become more reactive. For this reason they recombine with oxygen present in the air. This process causes a particular and immediate chemical reaction, the “cold combustion”.

Results of this reaction are organic and odorless short chain gases, such as carbon dioxide (CO2), water, etc.., normally present in air. So the air filtered by UV-SMELL-A during normal cooking, reduces the formation and deposits of fat and the consequent risk of fires, limiting also the growth of molds that feed usually on fats. UV-SMELL-A reduces the need of aspiration system cleaning and maintenance, extend filters’ life but, more importantly, offers the possibility to work safely.

UV-SMELL-A uses a UV-C amalgam lamp + O3 (Ozone) lamps.This type of bulbs, unlike the standard low pressure UV-C lamps, use a special “amalgam” made with metals, which optimize the UV germicidal power efficiency. Amalgam systems allows triple the UV-C emission compare to a low pressure lamp with the same length, and up to 16.000 hours life that guarantee a consequent cost saving. Furthermore the Ozone, persisting in air for few seconds before turning in simple oxygen, maximizes UV-C performances.

DISCOVER THE PRODUCTS

UV-SMELL-SQ

Applied inside kitchen hoods and aspiration systems, UVSMELL-SQ contributes significantly to minimize these problems;

fats are carbon and hydrogen compounds, with a structure made of complex chains. If fats are exposed to an intense UV-C irradiation, they absorb part of this powerful energy, and molecules, placed in a higher energy state, become more reactive. For this reason they recombine with oxygen present in the air.

This process causes a particular and immediate chemical reaction, the “cold combustion”. Results of this reaction are organic and odorless short chain gases, such as carbon dioxide (CO2), water, etc.., normally present in air.

So the air filtered by UVSMELL- SQ during normal cooking, reduces the formation and deposits of fat and the consequent risk of fires, limiting also the growth of molds that feed usually on fats.

UV-SMELL-SQ reduces the need of aspiration system cleaning and maintenance, extend filters’ life but, more importantly, offers the possibility to work safely.

UV-SMELL-SQ uses UV-C lamps and/or UV-C+O3 (Ozone) lamps, and it is the firts device in the market that can handle ozone or ozone-free lamps, alternatively or even combined together, according to clients’ needs.

In these kind of applications, UV power is often enough to reach great results, but ozone, persisting in air for few seconds before turning in simple oxygen, maximizes UV-C performances.

UV-STYLO-S

Applied inside kitchen hoods, UV-STYLO-S contributes significantly to minimize these problems; fats are carbon and hydrogen compounds, with a structure made of complex chains.

If fats are exposed to an intense UV-C irradiation, they absorb part of this powerful energy, and molecules, placed in a higher energy state, become more reactive. For this reason they recombine with oxygen present in the air.

This process causes a particular and immediate chemical reaction, the “cold combustion”. Results of this reaction are organic and odorless short chain gases, such as carbon dioxide (CO2), water, etc.., normally present in air.

So the air filtered by UV-STYLO-S during normal cooking, reduces the formation and deposits of fat and the consequent risk of fires, limiting also the growth of molds that feed usually on fats.

UV-STYLO-S reduces the need of aspiration system cleaning and maintenance, extend filters’ life but, more importantly, offers the possibility to work safely.

UV-STYLO-S uses UV-C lamps and/or UV-C+O3 (Ozone) lamps, and it is the firts device in the market that can handle ozone or ozone-free lamps, alternatively or even combined together, according to clients’ needs.

In these kind of applications, UV power is often enough to reach great results, but ozone, persisting in air for few seconds before turning in simple oxygen, maximizes UV-C performances.